It was mostly a matter of going under the playfield and unscrewing the mechanical pieces from the bottom. I then secured them, along with their corresponding screws, to the underside with tape or zip ties. Then I covered the holes with more tape.

The pop bumpers required some special care. Here's what they look like from below:

I removed the coil and still had to unsolder these two wires, which connect to the light socket, in order to remove the top mechanism.

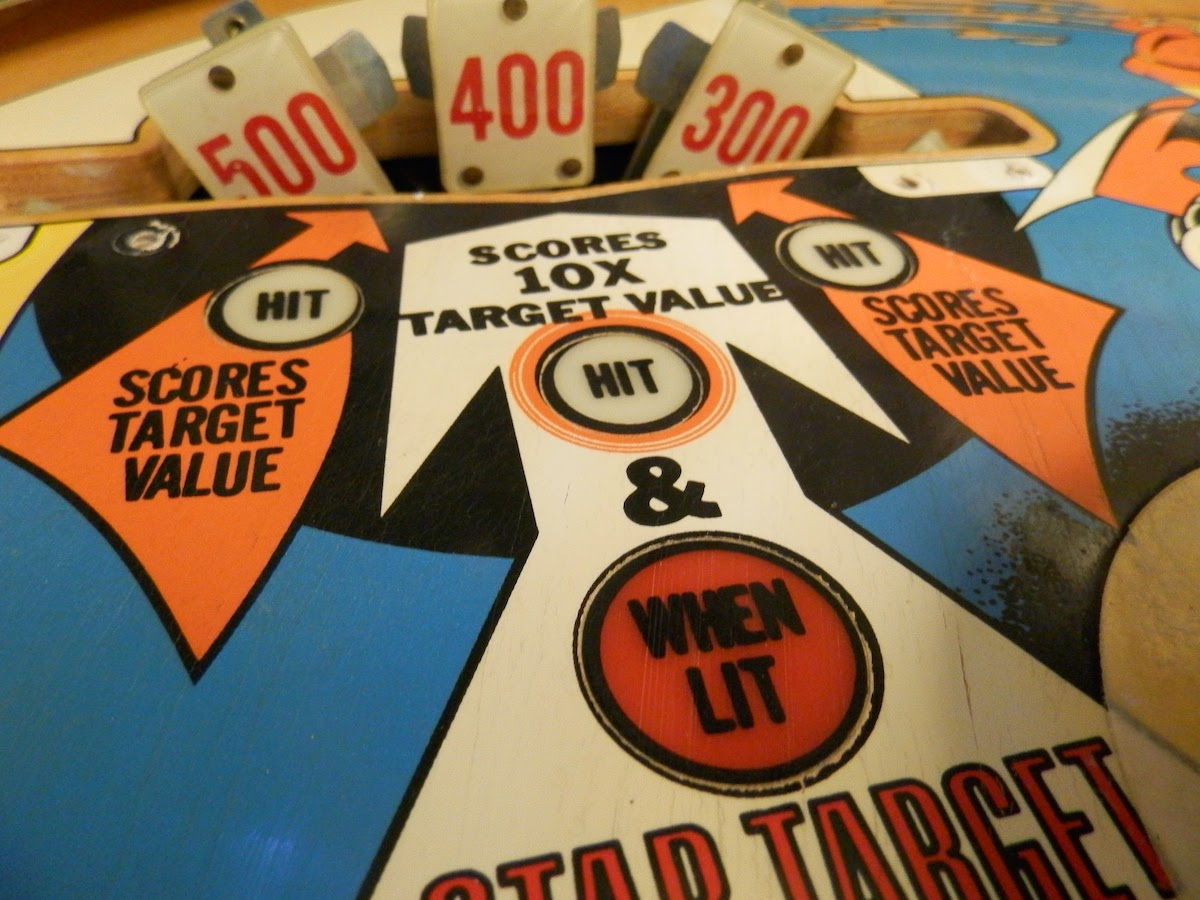

Here's what the playfield looks like sans targets and rollovers:

Finally, I needed to remove the wire ball guides and nails. A gentle pull with a pair of pliers and they came right out. I made sure to number and label each one so I can put them back correctly later.

Here's what the playfield looks like totally stripped:

Flat and ready for painting!